Maintenance shutdowns are frequently required to carry out maintenance (and other) activities that can only be done while the process is offline. Maintenance shutdowns are costly to implement and require intensive planning. A solid plan ensures that quality work gets done within scope, budget and the agreed timeframe. Bad planning and scheduling amplify costs, risk and duration.

All shutdowns are judged against four criteria:

- Were there any health, safety or environmental standard failures?

- Did the plant return to name-plate capacity in time?

- Was the shutdown completed within the agreed budget?

- Was the quality of the tasks completed, sufficient to ensure operational reliability?

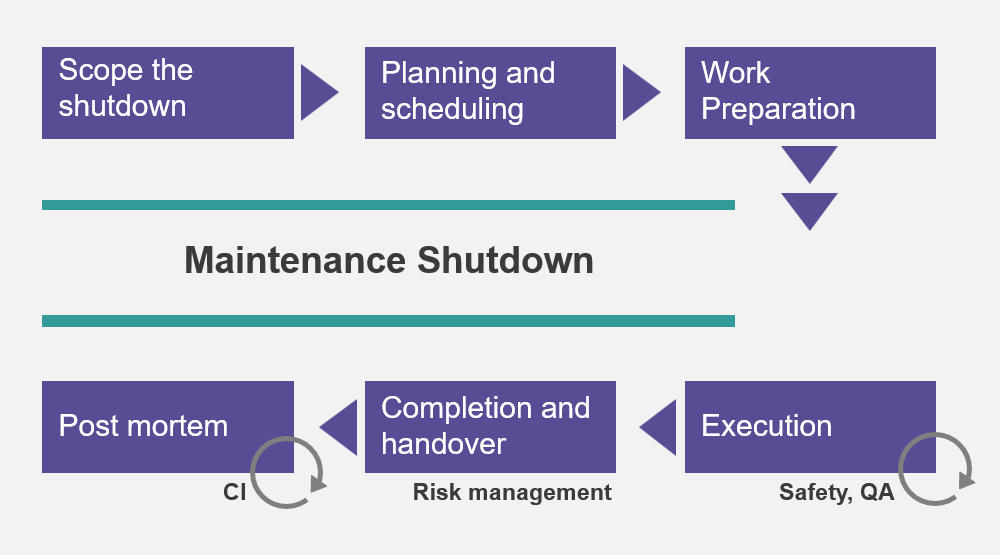

| An unsatisfactory result in any of these will invariably lead to escalations in time required and costs involved. Each criterion is a risk that must be managed throughout the shutdown life cycle. Maintenance planners are required to plan for shutdowns. However, they can easily fail in this task if the leadership team does not recognise, or provide sufficient time and consideration for the first and last stages of a shutdown framework. |  |

Core to the role of a qualified maintenance planner is the evaluation of risks throughout the planning and scheduling process. Successful shutdown planning and execution are born from a clear management framework that provides the planner with the parameters required to effectively evaluate risks as they arise.

So why shutdown?

The answer may seem blindingly obvious, but many organisations fail to further interrogate the response that 99.9% of maintenance engineers will tell you without even thinking – there is always maintenance that cannot be done while the plant is online. This is where the shutdown process starts to quickly unravel, as all eyes turn toward the enterprise asset management (EAM) system to see what work awaits in the backlog that cannot be done online.

Stop right there – and let’s consider a different approach: Begin with the end in mind.1

Yes, indeed, Stephen Covey’s Habit 21 applies to shutdowns too! Every shutdown needs to have clear and specific objectives as there will always be more work required than the available resources, budget and time. Without these specific objectives, scope creep and cost overruns quickly become the norm.

Shutdown objectives will include a range of outcomes from reliability enhancements, asset life extensions, capacity enhancements, replacement of obsolete technology, component replacements etc. The process of determining the exact scope of work to be done only begins once the objectives are clear and everyone is aligned that those are THE objectives. Discipline and rigour are required as the process of compiling a work breakdown structure (WBS) for the shutdown unfolds. Work that does not directly deliver on the agreed objectives must not be taken into consideration at this stage; no matter how important or urgent it might seem.

Scoping: The critical path

Pre-freeze activities: In this phase, the planner completes the high-level shutdown scoping and generates the work breakdown structure to provide the shutdown manager with the initial project plan. As the maintenance planner sequences and groups the activities together a “golden thread” (critical path) quickly emerges. These are the activities whose duration and order determine the minimum time frame required for the shutdown. The project plan is presented to the management committee. It is essential that everyone agree on:

- Every activity on the work breakdown structure is essential for the achievement of the agreed objectives

- The sequencing of the activities is logical and will ensure that all the activities are completed as efficiently as possible without escalating risk beyond acceptable norms

- High-risk, long lead time or complex contractual issues are highlighted and triggered for execution to avoid or minimise the risk of delaying the shutdown

- That the durations assigned to each of the activities are realistic and can pragmatically be achieved without escalating risk beyond acceptable norms

The acceptance of this critical path provides the boundaries for the planning and scheduling activities that will be done in preparation for the shutdown. The shutdown scope freeze is signed off once everyone agrees to the objectives, and the high-level activities to be included. Other activities will inevitably arise, and as tempting as it might be to “squeeze it in” and add it to the scope of work, the shutdown management team must be disciplined and rigorous to delay activities that are not aligned with the stated objectives to another opportunity.

Planning and scheduling

Post-freeze activities: The WBS is analysed and using advanced work scoping methods, is broken down to its component activities following the classic planning steps of work management:

- What must be done?

- Which trade or contractor is required?

- How long will the individual elements take?

- What materials (and their lead time) are required?

- Are there any special requirements ie scaffold erection, crane, special permits, complicated contract negotiations etc?

- What are the expected costs associated with the activity?

There needs to be a realistic expectation of the costs which will be incurred before the shutdown even begins. It is during the last planning step described above that individual cost components are tallied and compared against the agreed budget. Adjustments are made to the scope of the work or the budget to accommodate any potential risks.

It is at this point that work from the backlog might be considered – provided that it aligns with the agreed objectives for the shutdown and it will not cause any extension to the critical path.

Preparation

The preparation phase commences with your critical path clearly detailed, ensuring an accurate time and cost projection for the shutdown. The preparation phase is an opportunity to finalise the procurement logistics. The procurement process is a powerful aid to document lessons learnt in prior shutdowns. The lessons learned can be encapsulated in the specification or scope of work for your external service providers.

During the preparation phase quality issue risks that will potentially disrupt the start-up process are evaluated. A big challenges is quality of workmanship during the shutdown, and ensuring that defects are detected early. To mitigate this, consider having “hold” activities in your project plan for critical or high-risk activities where planned job observations (PJOs) or quality inspections are conducted as soon as possible after the critical work is completed. Planning to test equipment as the work is completed, and well before commissioning, provides everyone with enough time to manage any unexpected surprises.

Post-shutdown review

A post-shutdown review or post-mortem is easily overlooked once the adrenalin of the shutdown and its subsequent start-up has passed. The post-mortem allows one to consolidate on the lessons learnt, document requirements and specifications for future work and to reflect on the preparation effectiveness. The post-mortem provides an opportunity to recognise the short-cuts taken in the early stages that lead to unexpected surprises. It is the ideal juncture to optimise your shutdown framework to ensure that due consideration is given to:

- Objectives: Were they explicit enough, and was everyone aligned on what was to be achieved? Conversely, were they so vague that it became impossible to screen and prioritise the break-in work?

- Work breakdown structure: Did we pay enough attention to the details and the estimates? Were we optimistic or unrealistic in the estimates that we made? How well were we able to stick to the critical path estimates?

- Planning and scheduling: Did we allow sufficient time for the maintenance planners to do a quality job? Did procurement and our suppliers have sufficient lead time? What work was incomplete or unattended? This must be scoped and documented to ensure that everything is in place for the next opportunity.

- Preparation: Were we able to effectively assess the risks? Were the contingency processes in place sufficient to mitigate the risks? Could we have avoided any of the risks in their entirety?

Graduate planners who achieve their Maintenance Planner: Occupational Certificate (through the Pragma Academy) are provided with a robust shutdown framework model, and the tools and practical exposure to apply shutdown planning best practices within your organisation.

Contact us at Pragma.Academy@pragmaworld.net if you wish to find out more about our qualification programme.

Citation reference: 1. Stephen R. Covey – Habit 2: Seven habits of highly effective people (www.franklincovey.com)