The impact of ongoing power cuts on the SA industry

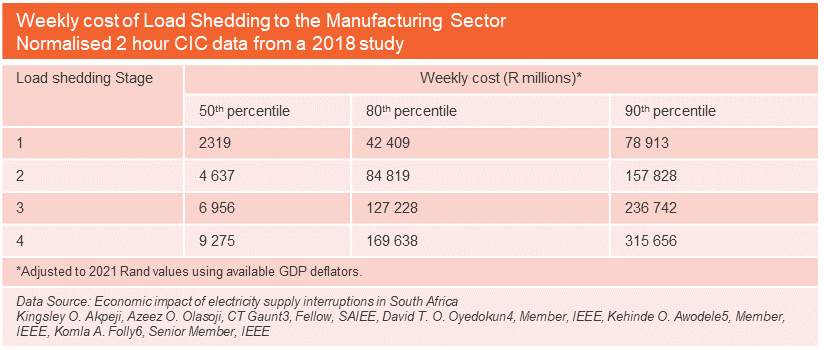

Load shedding has become an ever-present reality in South Africa. It has a massive effect on South Africa’s GDP, specifically in the manufacturing industry. In a study conducted in 2018, it was established that load shedding is costing the industry in excess of R 2bil per week.

Let’s face it – load shedding and power cuts are not going to disappear anytime soon in South Africa. It is therefore imperative that your backup power is always available to ensure business sustainability. In this article we will explore the cost of power cuts to your company with a specific focus on the importance of standby generators and possible solutions to mitigate the risk to your business.

Key industry challenges when power cuts occur

Generator reliability issues

- Controller not in Auto mode

- “Emergency Stop” activated

- Battery flat or stolen

- Switchgear not functioning correctly

Running out of fuel

- Fuel theft

- Insufficient monitoring of fuel levels

Cost transparency and predictability

- Lack of historical budget information

- High cost of reactive maintenance

- Servicing not done when specified

- Overcharging for maintenance

Impact of poor maintenance practices

- Statutory compliance work not tracked

- Remedial work not managed

- Fluid levels or leaks not monitored

- Maintenance work quality not confirmed

- Warranties not tracked or managed

Calculate your cost-saving potential

Have you ever considered the cost associated with your generator and the effect of these critical assets not operating when required? Based on market research and our Asset Health Management service, we have derived the costs that should be top of mind when considering this question.

Consider an average size generator of 550kVA used at a facility.

Estimated Replacement Value: R600 000

Cost-saving elements:

- Increase in asset life

- Reduce generator maintenance cost due to early failure detection

- Cost benchmarking

- Refuelling planning

- Reduce call-outs and after-hour work

- Reduce maintenance management resources

- Load testing cost

- Opportunity cost of generator not starting up once every 5 years.

TOTAL Estimated Saving per Generator (Monthly): R12 100

The largest cost-saving component is the opportunity cost of the generator not starting up and the business losing money as a result. Use the below formula to calculate the estimated monthly savings per generator for your business:

Monthly Saving equals 3455 + (Opportunity cost / 60 months).

Asset Health Management on Generators

Pragma provides an Asset Health Management solution for generators that will help you save on brand equity and financial losses while keeping your clients satisfied. Find out more about this cost-effective solution here.