Are your artisans always under pressure to try and fix endless and random equipment failures? We find that many organisations have a haphazard approach to maintenance management resulting in exhausted and negative resources, poor asset performance, uncontrolled maintenance expenses and mounting asset-related risks.

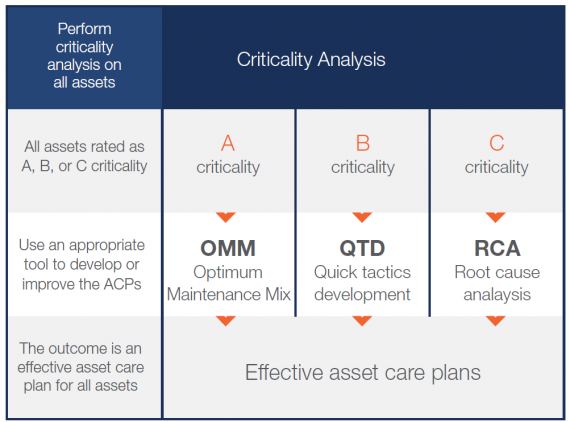

Good intentions won’t necessarily deliver effective or sustainable results. Experience has taught us that when you follow a structured approach to the development of tactical asset care plans (ACPs), you achieve significant and sustainable results.

Optimum Maintenance Mix

During our dealings with clients who struggled with breakdowns and non-tactical maintenance despite having ACPs in place, we went to the drawing board and developed a process that we call the Optimum Maintenance Mix process.

The approach combines the scientific methods of the following:

- Asset criticality

- Failure Modes and Effects Analysis (FMEA)

- Balanced maintenance tactics selection

- Maintenance task development.

The combination of asset criticality assessment with ACP development ensures a focus on the most critical assets, rendering immediate results.

Benefits of structured asset care plans

Since we started helping clients with the structured development of their ACPs, we have seen consistent results in the following areas:

Process efficiency

- Reduced administration for managing and updating ACPs.

- The effective use of time and resources. The ACP development approach focuses on spending time optimally based on the spread of the assets’ criticality.

- Following a formal process is followed built on best practices to ensure consistency in the development process.

- Progressing from a reactive to a proactive maintenance environment, towards more predictability.

Cost savings

- Reduction in maintenance and downtime cost owing to an improved mix of more cost effective condition-based maintenance and usage-based maintenance.

- Improved effectiveness of tactical maintenance leads to fewer breakdowns and results in cost reductions.

- Performance (reliability and uptime).

- Improved reliability and uptime owning to effective tactical maintenance.

Risk mitigation

- ACPs are based on scientific evaluation of asset-related risks and failure profiles.

- ACPs are not based on gut-feel, opinion or intuition, but on the collective experience and best practice.

Our approach to asset care plan development

Process: We will help you develop a set of standards to assess your critical assets, analyse their failure modes and develop tactical tasks. We will also provide you with criteria for selecting a balanced set of maintenance tactics. This choice of tactics is based on decision-tree logic, supported by a list of criteria that we have built up over many years of experience.

Software: We have developed software which we use to develop the ACPs. Although ACPs can be developed using a program such as Excel, we strongly discourage this as you will not have access to the value-adding and time-saving features of our software. Some of the features of the software include:

- Configuration of customised criticality models, such that different levels (groups) of assets can be assessed differently for criticality.

- The partitioning of assets’ systems into multiple levels of assets and components.

- The building of a Failure Modes and Effects Analysis (FMEA) tree.

- Extensive task configuration capability with customisable fields to provide for most task details required by industry.

- The software can be used as stand-alone tool, and batch integrates with other ERP systems.

- A set of reports, which include an ACPD progress report, a long-term work plan showing the required labour capacity for the developed ACPs and ACP for each asset.

History is kept of changes made to criticality analysis, FMEA and ACPs

Training – Critical to the success of ACPD is a thorough understanding of its principles. Our Academy offers courses that will instil knowledge, skills and competence. They also link ACPD in context to other asset management processes such as planning and scheduling, and focused improvement.

If you want to press the reset button on your poorly developed asset care plans, you can speak to us.