About this course

Give your maintenance management team a common understanding of what good maintenance looks like. This course will give them a logical model showing interfaces among all the elements, the best practices of each element and the benefits of doing it well.

Most maintenance engineers and supervisors end up managing maintenance activities without any formal training. This course is based on a logical model of maintenance management, covering the principles, best practices and benefits of each element, as well as the interfaces between them. The course is very interactive with lots of examples, exercises and guidelines, ending with a self-assessment and implementation roadmap.

Pragma has combined its 30 years of maintenance management experience with the accepted best practices from global standards, text books and guidelines to develop this course. If required, it can be customised to align with an organisation’s own maintenance blueprint and examples.

Outcomes

Describe good maintenance practices according to the Maintenance Management Model

Explain the maintenance objectives of improved performance and lower risk at optimal cost

Create a maintenance scorecard consisting of a balanced set of KPIs and targets

Describe the negative effects of reactive breakdown maintenance

Explain how the failure profile of components determine which maintenance tactics are applicable

Describe how maintenance work can be managed more effectively and efficiently

Explain how Maintenance can support Supply Chain to improve its material management

Make better contracting decisions and manage contractors more effectively

Explain the role of Production/Operations in ensuring reliable assets

Create a logical maintenance organisation with clear roles for everyone

Use the functionality of a maintenance information system to make better decisions

Interpret maintenance KPIs in order to identify opportunities for improvement

Develop a clear vision of what good maintenance looks like

Assess the Maintenance function and develop a maintenance improvement strategy

Introduction – The Maintenance Challenge

This module gives context to the course in terms of the global problem of ageing assets, terms and definitions, and the objectives of maintenance, using the Maintenance Management model as the driver.

Measuring and Managing Performance

This module introduces the PDCA cycle and the need for performance measurement. Key concepts are defined and a framework provided for a balanced maintenance scorecard. Finally, the role of daily meetings to review performance and drive improvements is discussed.

Asset Reliability

This module defines asset reliability and the role of

the reliability engineer. The different failure profiles

(age- related vs random), the P-F curve and the impact

of forced deterioration are unpacked. The calculation

and interpretation of MTBF is reviewed using

appropriate examples.

Maintenance Tactics

This module explains how asset criticality is defined and where it is applied. The four basic maintenance tactics are explained, how they are selected based on the components’ failure profiles, their packaging and implementation in the information system.

Maintenance Work Management

This module covers the 9-step process to manage maintenance work – the approval, planning, scheduling, allocation and execution of work. The roles of the people involved, the underlying best practices and the KPIs to measure the success of the process are explained using appropriate examples.

Material and Tools Management

This module gives learners insight into the Supply Chain processes and the effect on Maintenance and how certain bad maintenance practices (like squirrel stores) impact the effectiveness of material management.

Contractor Management

This module introduces some basic principles about making an outsourcing decision, selecting contractors and managing them as “external employees” according to the type of contract.

Operate for Reliability

This module covers the role of operational staff in asset reliability and performance improvement, by doing basic maintenance tasks like cleaning, inspections, minor repairs and assisting artisans with major work.

Roles, Structures and Competencies

This module gives an overview of a Maintenance structure and responsibilities. It covers all the important concepts related to training including competencies and assessment.

Asset Data and Information Management

This module explains the functionality of a typical maintenance information system. It covers the data management process for effective information, and how to manage changes to ensure up-to-date documentation.

Strategic Plans and Budgets

This module covers the strategic planning process – the development of an end-state maintenance vision, a 3-pronged gap assessment, and the development of a prioritised improvement strategy, with supporting budget.

Who should attend?

- Factory managers

- Engineering managers

- Managers maintenance

- Maintenance supervisors/ foremen

Format and duration

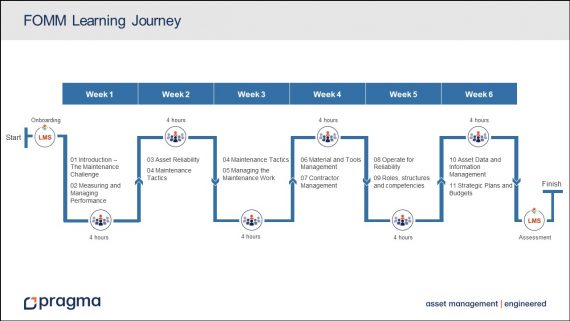

- 26 notional hours delivered via two options: 6x half-days of blended learning via a virtual classroom or 3 full days training in a physical classroom

- Online assessment

Take-aways

- A logical Maintenance Management Model

- Key considerations for implementing each element

- Maintenance management self-assessment

- Template for a maintenance management road map

Certification

- ECSA endorsed for 3 CPD points

- Aligned with the SAAMA designation for an Asset Management Practitioner