This course is an immersive exploration of the focused improvement (FI) process, providing learners with a comprehensive understanding of the methodologies for conducting FI projects. Through case studies and expert guidance, participants gain practical insights, enabling them to apply their knowledge effectively.

About this course

The course focuses on a standardised and systematic approach known as the IDMAIC process – Identify, Define, Measure, Analyse, Improve, and Control. Unlike methodologies for process reliability, IDMAIC concentrates specifically on enhancing asset reliability.

IDMAIC methodology: Unravelling complexity and ensuring success

IDMAIC is a robust methodology designed for addressing complex problems with significant consequences.

Learners will not only grasp the theoretical aspects but will also engage in hands-on applications of IDMAIC steps, gaining valuable experience beyond textbook knowledge.

Outcomes

Describe and apply the IDMAIC steps of focused improvement.

Define and specify a given problem based on the available information.

Explain how triggers are deployed in the IDMAIC process to address a certain scope.

Define how a mechanism may allow for self-evaluation of a project, allowing only certain FI projects to be addressed.

Define where focused improvement problems and opportunities might be found.

Identify how causal trees are used within the IDMAIC process and apply them where an asset is not complying.

Identify the cause(s) and root cause(s) of a problem using physical as well as latent and systemic causal trees.

Define and evaluate potential solutions to counter a problem’s root cause

Implement mechanisms to make successful solutions sustainable.

Explain how an FI process should be designed, implemented and managed.

Day 1

- Introduction: The focused improvement process, its problem-solving capabilities and its place in asset management.

- Different methodologies: Positioning IDMAIC, causal tree analysis and others relative to each other.

- Identification: Exposure to aligning triggers with process scope and ensuring approval for the right projects.

- Define: A rigorous methodology for uncovering real problems, exploring consequences, and understanding the environment.

- Application of the methodology to a case study, encouraging group collaboration and feedback.

- Introduction to Measure: Enhancing understanding of identified problems.

- Introduction to the Causal Tree methodology: Ideal for dissecting non-conformance in physical assets, to be applied in the case study on Day 2.

Day 2

- Application of causal tree methodology to the case study

- Feedback session on the outcomes of their initial application.

- Deep dive into the Measure phase: Introduction to various techniques, with practical application to the case study.

- The Analyse phase and people/system evaluation: Delving into the Analyse phase, emphasising the evaluation of people and systems

as potential causes. (Learners must provide evidence supporting their findings on the causal trees.)

Day 3

- Case study progress by building on Day 2’s outcomes and integrating the findings into the ongoing improvement process.

- Introduction to the Improvement phase: A challenge to generate multiple solutions for the identified causes.

- Emphasis on improvement opportunities: Recognition that defect elimination may necessitate elements of improved design.

- Final considerations: Finalisation of the financial aspects during the Improvement phase, and understanding the economic impact of the proposed solutions.

- Tools for solution generation: Introduction different tools to generate diverse and effective solutions, and applying them to the ongoing case studies.

- Integration of design and defect elimination.

Day 4

- Introduction to Control: Emphasis on ensuring sustainable solutions and project closure.

- Group presentations of case studies.

- Evaluation of FI process maturity:

Practical tips and best practices for improving or establishing FI processes in the workplace. - Interactive session: Discussing and sharing experiences in evaluating and enhancing FI processes.

- Online assessment, feedback and Q&A.techniques

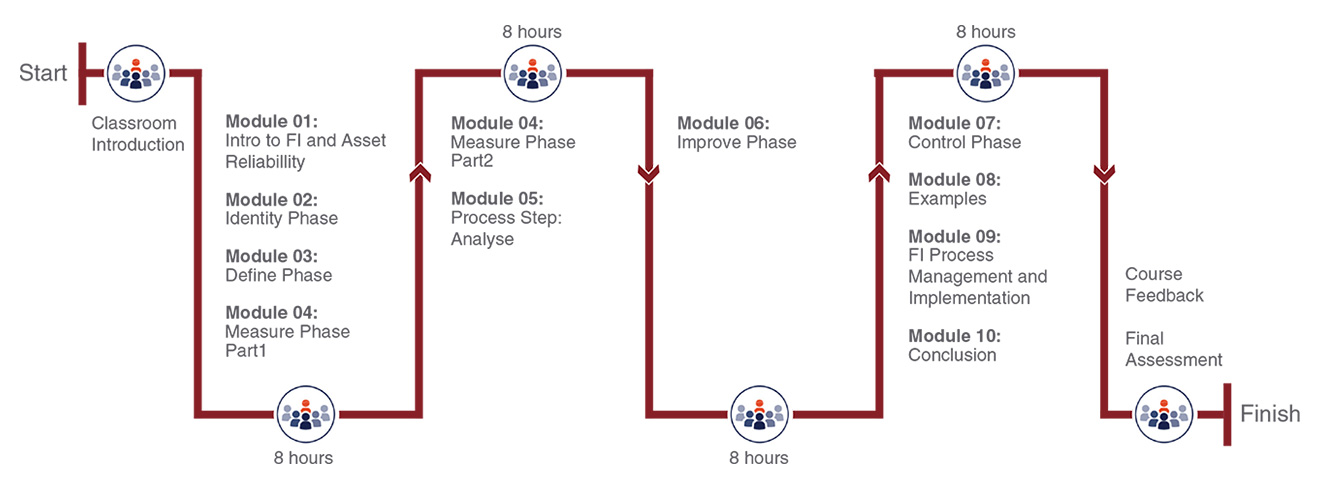

Learning journey

Who should attend?

- Reliability engineers

- Section engineers

- Asset care engineers

- Anyone involved in the focused improvement processes

Format and duration

- 32 notional hours delivered

via two options:- 4 days of blended learning via a virtual classroom, or

- 4 days of training in a physical classroom

Note: Laptops are required for both course formats

Take-home tools

- The real-life case study

- Lessons learnt from a facilitator who is an asset management consultant and experienced FI practitioner

- Causal trees (cause-and-effect diagrams)

Certification

- Learners completing this training can obtain SAAMA CPD points.