About this course

This course is highly practical and explains the fundamental principles and processes of an effective maintenance system in straightforward language. It also emphasises the important roles of the artisans and technicians to ensure success and support the company-wide roll-out of maintenance management.

This course is aimed at the frontline maintenance staff (artisans, technicians, assistants and operators) to explain to them what good maintenance look like, how all the maintenance activities are linked to each other and their role in this process. It uses practical examples and real life scenarios to explain the basic concepts and principles.

For best results, it should be presented in-house, customised with site-specific examples, objectives and the results of a recent maintenance maturity assessments.

Outcomes

Describe what “good maintenance” looks like

Explain the benefits of good maintenance practices for the company and themselves

Describe the work order cycle and the role of everyone in it

Explain the importance of giving complete and correct feedback on work orders

Explain the negative effects of breakdowns and reactive maintenance

Explain the difference between normal wear and tear of components and “forced deterioration”

Describe the maintenance tactics and when each one should be used

Explain what they can do to solve some of the spare part problems on site

Explain the PDCA cycle and how they should use KPIs to drive improvement

Explain the steps in root cause analysis and when RCA should be applied

1 Why Are We Here?

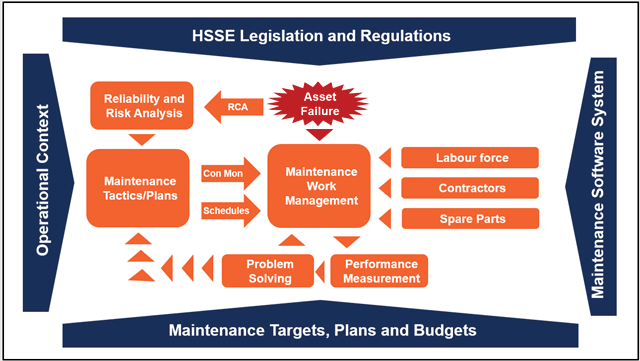

This module sets the scene and creates the context for the rest of the course, by covering the company’s maintenance objectives and strategic plans (to be customised), listing the learners’ biggest frustrations and introducing the Maintenance Model.

2 Maintenance Work Management

This module covers the day-to-day world of maintenance work management by introducing the work order cycle, the benefits of proper planning and scheduling of work, how work is allocated and the importance of good work order feedback

3 Breakdowns – Enemy No 1

This module explains the high cost and negative impact of breakdown repair vs preventive maintenance. It also explains how urgent work bypasses the planning and scheduling steps, as well as how forced deterioration reduces asset reliability, and the importance of proactive precision maintenance and reactive RCA to eliminate breakdowns

4 Preventive Maintenance

This module explains how breakdowns can be prevented through different maintenance tactics, which are based on a deep understanding of the failure profiles of components (age-related vs random, as well as whether a P-F interval exists.)

5 Spare Parts

This module gives learners a better understanding of the complexity of a supply chain. It covers the factors impacting the stockholding of spares and the effect of Maintenance of effective procurement and warehousing of spares, especially squirrel stores. It also explains the rotable management process.

6 Performance Measurement and Improvement

This module focuses on the PDCA cycle and the importance of selecting the right maintenance KPIs, with examples. It also explains how the KPIs should be reviewed in meetings, resulting in improvement actions to address gaps.

Note: For best effect, the course content should be customised with company-specific examples and conditions

Who should attend?

- Maintenance artisans

- Maintenance technicians

- Chargehands

- Maintenance apprentices

- Production technicians

- Production operators

Format and duration

- 1-day face-to-face facilitates training

- 8 notional hours

Take-home tools

- Model of maintenance activities

- Handout of the key learning points

Certification

- None