A key theme that Original Equipment Manufacturers (OEM) face is the concept of customer-specific customisation to serve the purposes of customer maintenance contracts.

This was one of the elements that emerged during a roundtable workshop that Pragma hosted at their Maarssen office in the Netherlands on 20 March 2019.

Henk Wynjeterp, Pragma General Manager, hosted five invited OEM clients to discuss various challenges in developing OEM maintenance plans and to share information and learnings between non-competitive peers.

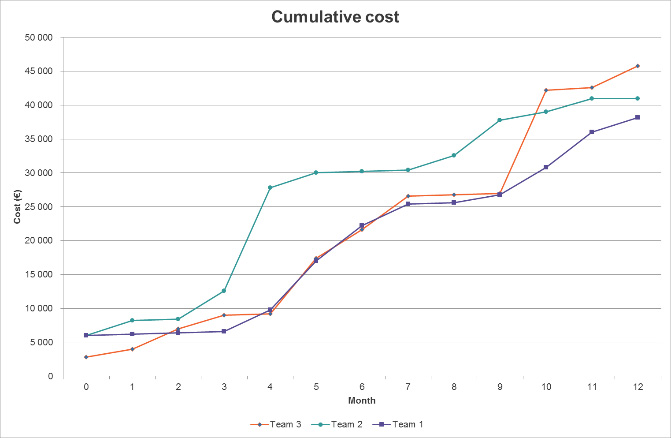

The workshop started with 12 rounds of Pragma’s Optimum Maintenance Mix (OMM) game, where the participants were divided into three mixed teams and competed to maintain their assets to the lowest total operating cost. Team 1 managed to contain their unplanned stops better and ended as the winning team. The OMM game provided a perfect start to the discussion as the participants became acquainted and at the same time, the challenges in maintenance plan development became practical.

Customised maintenance contracts

During the workshop, the focus of the discussion turned to the customisation of customer-specific maintenance contracts to serve the purposes of customers. These customisations relate to the equipment specifications and operating conditions. To address this challenge, a modular approach is best suited for both the equipment bill of material (BOM) and the maintenance tasks.

Equipment specification customisation requires up-to-date information on the current modifications and versions of the sub-assemblies and BOM. Such a modular approach needs to be embedded at the R&D departments already, to facilitate for example separate drawings which can be put together rather than redeveloped for each machine option or version. Maintenance task customisation needs to adapt to the customer maintenance capacity and risk profile. A big challenge that OEMs face is that the customer has less and less time for maintenance and this requires clear understanding and decisions on what to do within the available time. Developing maintenance tasks with automatic options and rules functionality will reduce customisation input from the project and contract managers and assist with timeous planning of the required spares and resources.

Industry 4.0

The participants are all excited about the opportunities that Industry 4.0 bring and have done various levels of experimentation. Remote assistance technology such as embedded cameras and smart glasses are used to support technicians and customers with fault finding and repairs reactively. Online monitoring is the focus of their current development to enhance their maintenance plans with condition-based information. This information will enable smarter maintenance decisions in support of equipment performance.

Pragma received positive feedback from the group and ideas were shared to feed into the planning for the next roundtable workshop.

More about the Optimum Maintenance Mix game

The optimum maintenance mix (OMM) methodology developed by Pragma is an asset care plan development process based on the specific objective of assisting companies in developing and improving the asset care plans for their physical assets. By playing the OMM game, the seven implementation steps and the importance of choosing the right tactic for each application are identified in a practical and fun way.

For more information about future roundtable discussions contact [email protected]