Good reliability engineering forms the cornerstone of an organisation’s ability to deliver its asset management objectives. In our first article on this topic, The Role and Importance of Reliability Engineering, we discussed the role and responsibilities of a reliability engineer. We looked at where and how reliability engineers (REs) fit into an organisation, the data they require, their key challenges, and possible solutions to address these challenges. The field is still developing and growing. Engineers often ask what the essential skills and requirements are that they need to grow in this field. In this article, we elaborate on the training and learning pathways available to aspiring reliability REs.

Reliability Engineering Learning Pathways

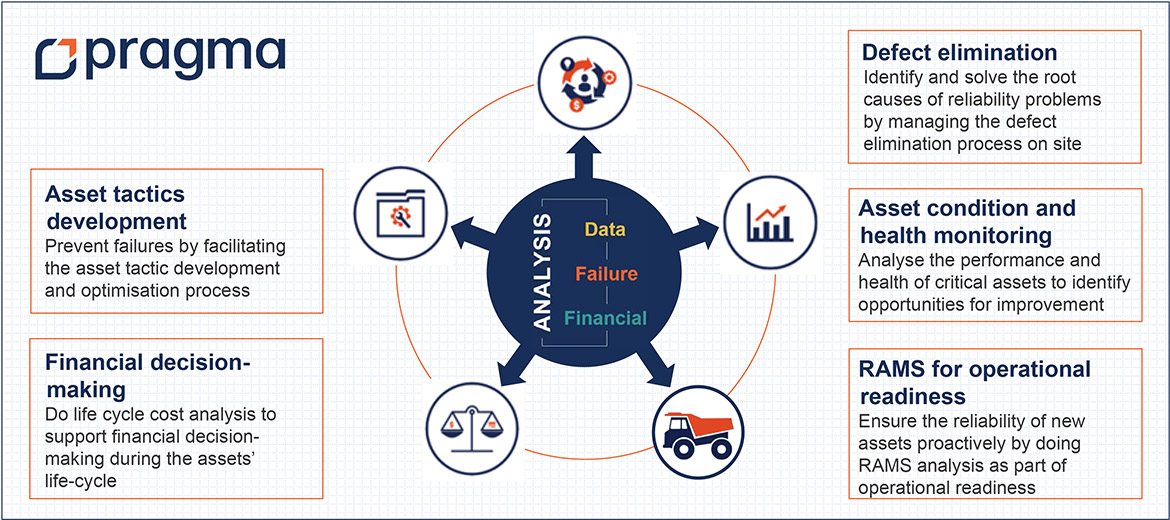

With its team of engineers and learning specialists, the Pragma Academy combines asset management consulting expertise with learning best practices to create structured skills development and role-based learning. Tapping into 30 years of asset care and asset management intellectual property, the Academy has compiled a comprehensive learning pathway. This learning pathway makes use of blended asset management training courses to address a reliability engineer’s growth, skills, and competency in their environment. The following key learning courses form part of our recommended learning pathway for a RE.

The Asset Management Landscape

This course provides a holistic view of asset management and the relationship between the different elements defined by the Global Forum for Maintenance and Asset Management (GFMAM). It is aimed at decision-makers responsible for implementing asset management in the organisation and others who need to support them.

Measuring and Managing Performance

This course enables learners to develop a balanced scorecard of asset management KPIs linked to asset management objectives and deployed to various teams and individuals throughout the organisation. It also covers the setting of SMART targets for these KPIs based on benchmarking. Finally, it covers a measurement plan to define data sources, measurement frequency, display format, accountabilities and discussion forums.

Basic Data Analysis

The course aims to make learners data literate. It covers basic information management concepts and uses a structured process to clarify the decisions that have to be made, the information required and the data that has to be collected. Learners do practical exercises with real scenarios and data sets.

Reliability Engineering Practice

This course equips reliability engineers with the skills to improve the reliability of critical assets and the processes or systems that they link to. It covers the role of an RE and fundamental RE analyses in a practical way – failure analysis as a basis for asset tactics, hazard rates, MTBF (Mean Time Between Failures) and Reliability Block Diagrams/Modeling. Learners also get to develop a RE roadmap for their sites.

Maintenance Plan Development

This practical and hands-on course is aimed at giving the engineering team the skills to develop or review maintenance plans for their critical assets. It is based on the proven Reliability Centred Maintenance (RCM) methodology but has been adapted for a more practical and efficient application. Learners will play the popular Optimum Maintenance Mix (OMM) Game for practical application.

Condition Monitoring Essentials

This course provides an overview of the most common condition monitoring techniques, applications and benefits, including techniques such as partial discharge for electrical equipment. It makes extensive use of practical examples and case studies to demonstrate the different techniques.

Structured Problem Solving

This course gives learners a structured methodology to solve problems. It uses the Define, Measure, Analyze, Improve and Control (DMAIC) methodology and provides learners with a variety of supporting tools that are applied practically during each of the DMAIC steps. Enabling a structured defect elimination process.

Financial Decision Making

This course equips engineers to make data-driven and financially founded decisions about assets. They learn how to calculate the life cycle costs of different asset options, quantify the value of improvement projects and compile a sound business case to motivate their recommendations.

Spare Parts Optimisation

This course equips engineers to optimise the stock levels of spare parts, based on a scientific analysis of the spares. They will learn how to classify spare parts on a 4×2 grid and apply a proven algorithm to calculate the optimal stock levels based on usage, costs, lead time and criticality.

Throughout the learning pathway journey, there will be an emphasis on soft skills, including facilitation skills, communication skills, conflict handling, assertiveness, presentation skills and more.